SILO – automated atorage and retrieval system

The SILO automated atorage and retrieval system is a high-quality technological solution that streamlines operational processes in a company by optimizing the storage of large quantities of items. Process automation increases work efficiency related to the error-free flow of goods, significantly contributing to cost reduction.

TEMREX vertical storage modules will elevate your company to the next level of operation. They will not only help maximize work efficiency, save time, and reduce errors, but also free up additional workspace, allowing for further activities.

The SILO automated storage system is a reliable tool applicable across many industries. It excels wherever time, precision, and safety are paramount, whether in a warehouse, extensive libraries, or archives.

SILO is a response to the individual needs of each Client and is always created according to their clearly defined guidelines. A wide range of additional equipment options makes it unparalleled in the market.

Gallery

Benefits

The SILO automated storage system is a flexible and functional tool that enables:

- MAXIMUM SPACE OPTIMIZATION

- ORGANIZATION OF ITEMS ON SHELVES

- SIMPLIFICATION OF INVENTORY MANAGEMENT

- FAST AND ERROR-FREE ACCESS TO SPECIFIC ITEMS

- PROTECTION OF VALUABLE RESOURCES

- INCREASED WORK EFFICIENCY

- APPLICABILITY ACROSS MANY INDUSTRIES

MAXIMUM

utilization of free space

FULL AVAILABILITY

of resources 24/7

TIME SAVINGS

thanks to automatic item location

PROTECTION

of resources and access restriction

CUSTOMIZATION

to individual Client needs

EASY OPERATION

fast product location

PRODUCT FEATURES

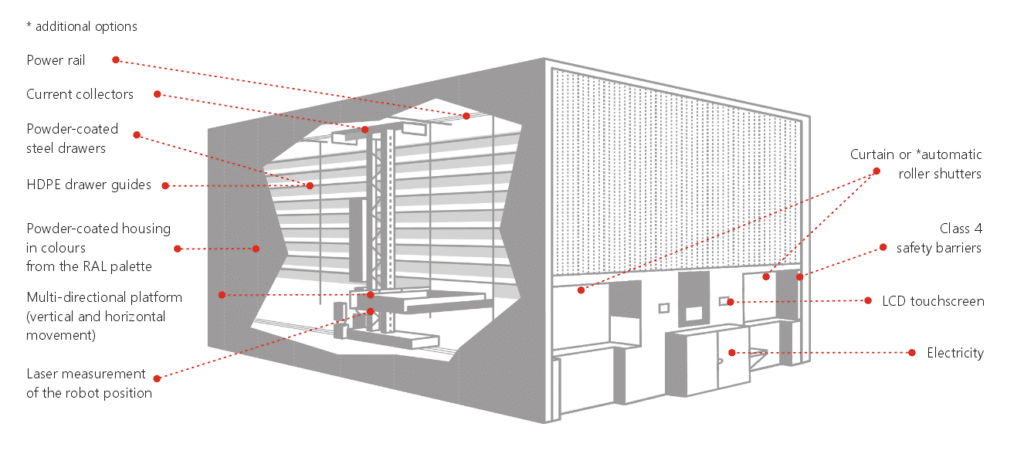

The design of the SILO automated storage system consists of two shelving units and a robot moving in the central aisle. PE-HD sliding strips under the drawer guides facilitate item placement and effectively minimize friction.

The electrical installation is supplied to industrial standards,

and high-quality electronic components are readily available,

ensuring reliability and quick service.

The design of the SILO automated storage system consists of two shelving units and a robot moving in the central aisle.

The electrical installation is supplied to industrial standards,

and high-quality electronic components are readily available,

ensuring reliability and quick service.

Light curtains are designed to protect the machine operator

and activate automatically during shelf movement. Interruption of the beam causes the device to stop.

Powder coating ensures aesthetic and durable corrosion protection and allows for color customization within the RAL palette.

The shelving unit is equipped with an LCD control keypad, offering access restriction via code. This solution allows for easy and clear machine operation.

Drawers provide excellent rigidity thanks to reinforced crossbars, which eliminate the problem of drawer deflection, thus removing the need for load distribution. PE-HD sliding strips under the drawer guides facilitate item placement and effectively minimize friction.

FAST AND ERROR-FREE ITEM LOCATION

POWDER COATING

ROBUST METAL CONSTRUCTION

ADDITIONAL OPTIONS

IDENTIFIER READER

access to items in the SILO automated storage system can be secured using a proximity card reader tailored to the Client’s identification technology, allowing existing identifiers to be used as an access mechanism

ZONE INDICATORS

the SILO automated storage system can be equipped with zone indicators, configurable every 25 mm. This allows for the creation of dozens, several, or one large zone, depending on needs and the stored assortment. Indicators are activated from the system administrator level, and zones interact with the software, facilitating quick item retrieval by the operator

PROTECTION OF GOODS IN THE ELECTRONICS INDUSTRY

it is possible to equip the SILO automated storage system with an ESD protection system. This involves using galvanized guides both inside the machine and on the sides of the shelves, as well as installing additional brushes to remove electrostatic charges from the shelf and the entire machine, allowing for the storage of components sensitive to these factors

STORAGE IN A CONTROLLED ENVIRONMENT

this is an additional option for use in conditions requiring continuous control of air parameters. The SILO automated storage system allows for storage in a controlled environment (ventilation, air conditioning, humidity control system, temperature). Additionally, fire and gas sensors can be installed.

VERSATILE ACCESS

the SILO automated storage system can be designed with multiple access windows (front/rear, sides of the machine), allowing several operators to work simultaneously. If items are stored in the basement and retrieved on an upper floor, the system enables multi-floor operation.

ELECTRIC CURTAIN

the automated storage system can be equipped with an electric curtain that secures goods.

WARRANTY

TEMREX devices are covered by a two-year warranty for transport, equipment, and accessories, excluding consumables subject to wear during normal operation. The warranty also includes access to mechanical and IT hotlines. After the first year of warranty, it is possible to extend it for subsequent years.

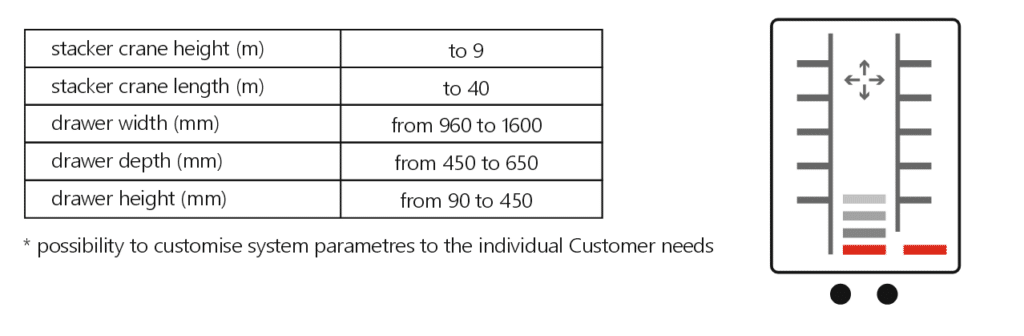

Technical Specifications