JUMPER – vertical lift module

The JUMPER vertical lift module is a high-quality technological solution that streamlines operational processes by optimizing the storage of large quantities of items. Process automation increases work efficiency for fast and error-free goods flow, significantly contributing to cost reduction.

TEMREX vertical storage systems will take your company to the next level of operation. They will not only help maximize work efficiency, save time, and reduce errors, but also free up additional workspace, allowing for further activities.

The JUMPER vertical lift module is a reliable tool applicable across many industries. It excels wherever time, precision, and safety are critical, whether in a warehouse or a workshop environment.

JUMPER is a response to the individual needs of each client, always built according to their clearly defined guidelines. A wide range of optional equipment makes it unrivaled in the market.

Gallery

Benefits

The JUMPER Vertical Lift Module is a flexible and functional tool that enables:

- MAXIMUM SPACE OPTIMIZATION

- CAPACITY TO STORE UP TO 60 TONS OF ITEMS IN THE MACHINE

- ORGANIZED ITEM STORAGE

- FAST AND ERROR-FREE ACCESS TO SPECIFIC ITEMS

- SECURE PROTECTION OF VALUABLE ASSETS

- INCREASED TEAM WORK EFFICIENCY

- APPLICABILITY IN MANY INDUSTRIES

MAXIMUM

utilization of free space

FULL AVAILABILITY

of resources 24/7

TIME SAVINGS

thanks to automatic item location

PROTECTION

of assets and restricted access

CUSTOMIZATION

to individual client needs

EASY OPERATION

fast product location

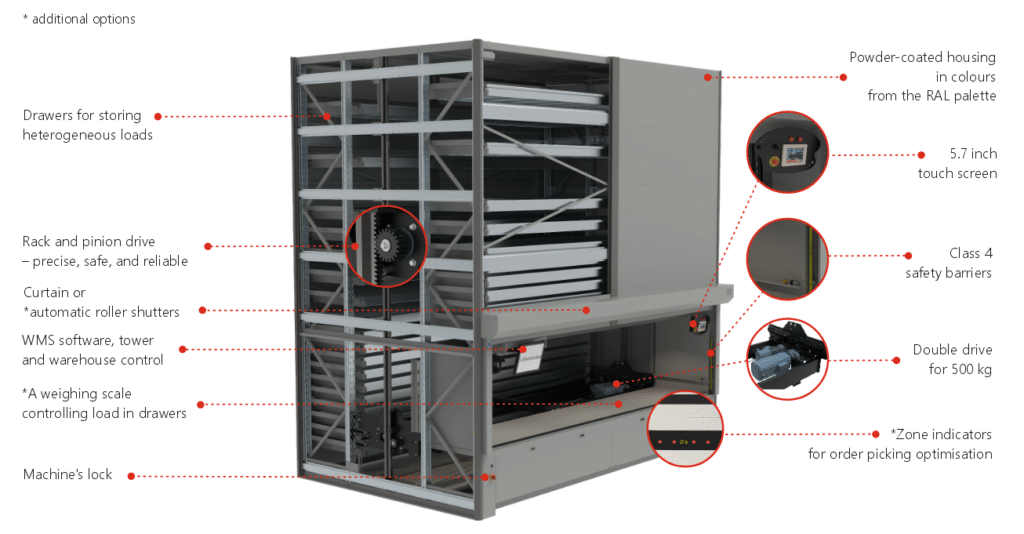

PRODUCT FEATURES

The use of a rack and pinion system for moving the working platform minimizes the risk of failures and facilitates access to electronics and automation, significantly shortening service intervention times,

as well as periodic inspections and maintenance work.

The rack’s design can accommodate 60 tons of goods.

The JUMPER Vertical Lift Module consists of two vertical structures with trays (at the front and rear of the rack) and a platform moving between them. It retrieves the user-selected tray and delivers it to the access opening. The machine’s impressive operating speed minimizes item retrieval time.

The use of a rack and pinion system for moving the working platform minimizes the risk of failures and facilitates access to electronics and automation, significantly shortening service intervention times,

as well as periodic inspections and maintenance work.

The rack’s design can accommodate 60 tons of goods.

The JUMPER 500 rack (capacity up to 500 kg) utilizes two vertical and two horizontal motors, allowing for quick tray access, even under maximum load.

The JUMPER 300 rack platform (capacity up to 300 kg) is equipped with a single drive.

Trays provide excellent rigidity due to reinforced crossbars, eliminating tray deflection and removing the need to distribute the load.

PE-HD sliding strips under the tray guides facilitate item placement and effectively minimize friction.

The rack’s design can accommodate 60 tons of goods.

Light curtains are designed to protect the machine operator

and activate automatically during shelf movement. Interruption of the beam causes the device to stop.

All automatic and electrical components are located under the workstation. The control cabinet ensures the highest level of safety for technicians entering the machine.

Powder coating guarantees aesthetic and durable corrosion protection, offering color customization within the RAL palette.

The rack is equipped with an LCD control keypad, offering access restriction via code assignment. This solution allows for easy and clear machine operation.

FAST AND ERROR-FREE ITEM LOCATION

POWDER COATING

ROBUST METAL CONSTRUCTION

ADDITIONAL OPTIONS

ZONE INDICATORS

The JUMPER rack can be equipped with zone indicators, configurable every 25 mm. This allows for the creation of dozens, several, or one large zone, depending on needs and the stored assortment. Indicators are activated from the system administrator level, and zones integrate with the software, facilitating quick item retrieval by the operator.

GOODS PROTECTION IN THE ELECTRONICS INDUSTRY

The JUMPER vertical lift module can be equipped with an ESD protection system. This involves using galvanized guides both inside the machine and on the sides of the shelves, and installing additional brushes to remove electrostatic charges from the shelf and the entire machine, allowing for the storage of components sensitive to these factors.

STORAGE IN A CONTROLLED ENVIRONMENT

This is an optional feature for use in conditions requiring continuous air parameter control. The JUMPER vertical lift module allows for storage in a controlled environment (ventilation, air conditioning, humidity control system, temperature). Additionally, fire and gas sensors can be installed.

VERSATILE ACCESS

The JUMPER vertical lift module can be equipped with a dual front/rear access system. This allows two people on opposite sides of the rack to retrieve items from two different trays simultaneously. The working basket will serve each side sequentially. Dual item positioning must then be provided.

The JUMPER rack can also be equipped with a dual top/bottom access system. This allows two people at different levels of the rack to retrieve items from two different trays simultaneously. The working basket will serve the levels sequentially.

ELECTRIC CURTAIN

The rack can be equipped with an electric curtain, which protects the goods.

WARRANTY

TEMREX devices are covered by a two-year warranty for transport, equipment, and accessories, excluding consumables subject to wear during normal operation. The warranty also includes access to mechanical and IT hotlines. After the first year of warranty, it is possible to extend it for subsequent years.

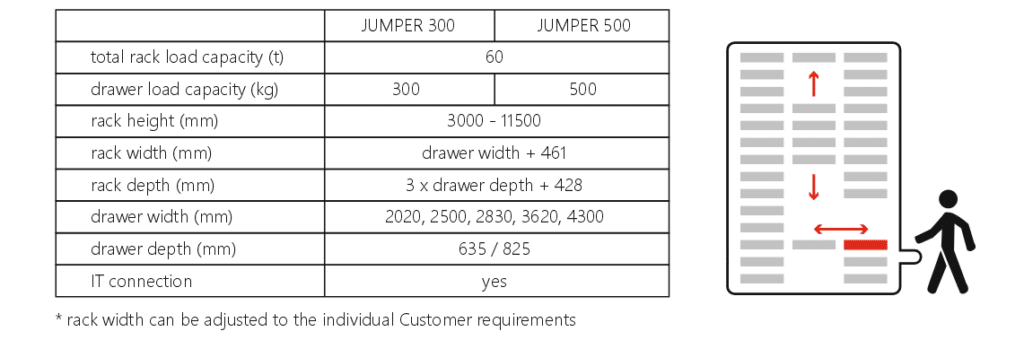

Technical Specifications